The Solution of Fanless SPS and Application

Dr. Leon Ku/ Research and Development Dept.

Normally, SPS with fan built-in has a certain weakness such as unavoidable noise, vibration, additional power consumption, unexpected mechanical failure, short term reliability, dust debris, etc. On the contract, fanless SPS are smaller, more reliable and more flexible with lower noise. For the understanding of thermal characteristics of fanless SPS and SPS with fan built-in, different thermal dissipation methods of SPS will be introduced below.SPS efficiency and power loss

Efficiency is the percentage ratio of total output power to input power. This is normally specified at full load under nominal input voltage. It is impossible to attain 100 % efficiency due to energy dissipated in the form of heat in passive and active components, such as switching devices, junction-based devices, capacitors, inductors, and so on. However, it is still possible to achieve above 95% efficiency by suitable electrical design, thermal design and component chosen. Electric characteristic and dissipation could be affected due to low energy efficiency, and excessive power lose can even decrease the life time of power supply, as well as deviation of electric characteristic performance.

SPS power levels and thermal dissipation methods

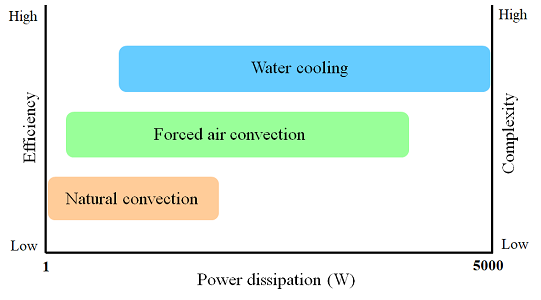

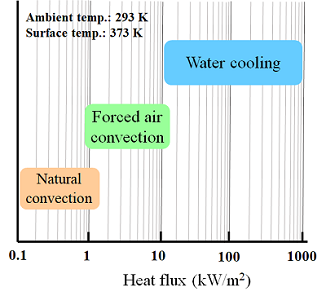

Based on different application, thermal dissipation methods can be different. Generally, natural convection, forced convection, and water cooling are common thermal dissipation methods and possess different thermal dissipation capabilities. Please refer to the following description of comparison based on different thermal dissipation methods.

(1) Comparison of heat transfer coefficient between different thermal dissipation methods

|

Heat dissipation method |

Heat transfer coefficient (W/m2K) |

|

Natural convection |

3-12 |

|

Forced air convection |

10-100 |

|

Water cooling |

3000-7000 |

(2) Comparison of heat dissipation capability between different thermal dissipation methods

|

|

From the table and graph above mentioned, it is obvious that water cooling possesses higher thermal dissipation capabilities, but a higher cost on system mechanism design is expected. Comparison between three different thermal dissipation methods of SPS includes advantage, disadvantages, and applications as shown in the table below.

The brief introduction of MEAN WELL high power fanless SPS products

The features of UHP/PHP series SPS are shown below include smaller dimension (size reduction about 50%), high operating efficiency, wider temperature operating range, covering wide safety approvals and high value (performance/price) for all kinds of applications. The UHP/PHP series are the best choices for integrated into your end system.

- Compact design to provide the solution for modern miniaturized equipment.

- Fanless design is suitable for equipment used in a silent environment and increased reliability in the system as an extra benefit.

- High efficiency and low power consumption to allow better energy saving on the final system

- -30 ~ +70 ℃ wide operating temperature suitable for various environments or installations.

- Certified by UL/TUV62368-1, IEC/EN60950-1 regulations.

- Meet IEC/EN60335-1, EN61558 OVC III regulations.

- Operational altitude up to 5000m.

UHP/PHP series SPS have fanless and half encapsulated design, can provide the best solution for precision instruments, charging stations, distribution board/cabinet, robot applications for industrial4.0 and ITE equipment.

The brief comparison show in the table below gives the quick reference of UHP/PHP series SPS to identify the major difference:

| UHP-500 | UHP-750 | UHP-1000 | UHP-1500 | UHP-2500 | PHP-3500 | |

| Cooling method | Passive cooling | Passive cooling | Passive cooling | Passive cooling | Passive cooling | Water cooling |

| Input voltage | 90~264Vac | 90~264Vac | 90~264Vac | 90~264Vac | 90~264Vac | 90~264Vac |

| Output voltage | 4.2/ 5/ 12/ 15/ 24/ 36/ 48V | 12/ 24/ 36/ 48V | 24/ 48V | 24/ 48V | 24/ 48V | 24/ 48V |

| Efficiency | 95% | 95% | 96% | 96% | 96% | 96% |

| Communication interface | ─ | ─ | ─ | CANBus PMBus |

CANBus PMBus |

CANBus PMBus |

| Dimension (L x W x H mm) |

232*81*31 | 237*100*41 | 240*115*41 | 290*140*41 | 310*140*60 | 380*140*60 |